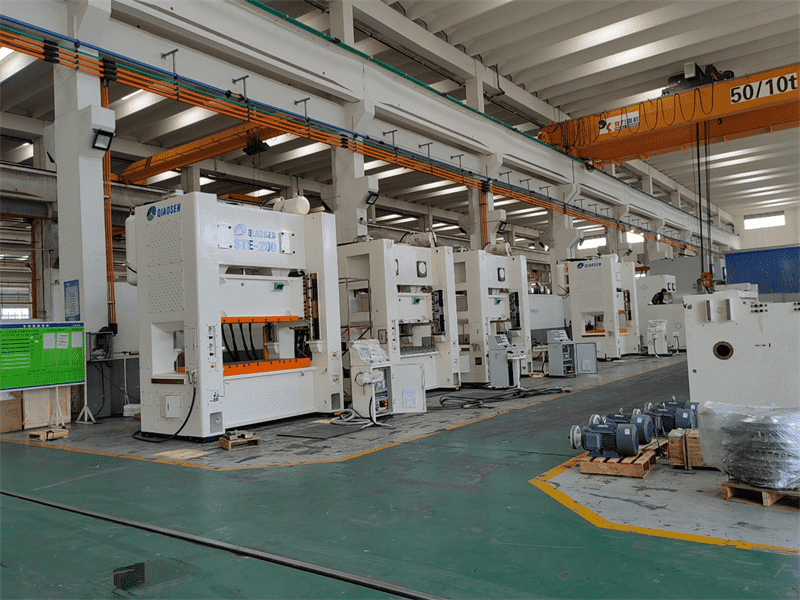

Mochine oa khatiso ke mofuta oa lisebelisoa tse sebelisoang haholo lefapheng la indasteri.Mosebetsi oa eona o ka sehloohong ke ho fetola thepa ea tšepe hore e be libopeho le mefuta e sa tšoaneng ea lihlahisoa ka ho etsa mochine oa khatiso.Ts'ebetsong ea tlhahiso, boemo ba ho sebetsa ba mochine oa khatiso oa mechine bo bohlokoa haholo.Hang ha ho hlōleha kapa ho senyeha ho etsahala, e ke ke ea ama ka ho toba tsoelo-pele ea tlhahiso, empa hape e tla ba le phello e tebileng bophelong ba tšebeletso ea thepa.Ka hona, mokhoa oa ho boloka le ho boloka mochine oa khatiso ka katleho o fetohile bothata bo ke keng ba hlokomolohuoa ke mosebeletsi e mong le e mong oa tlhahiso.

1. Tlhokomelo ea holim'a holim'a mechine ea khatiso

Tikoloho e sebetsang ea mechine ea khatiso e batla e le thata, 'me ho bonolo ho silafatsoa ke lerōle le lengata le likhase tse senyang.Ho sireletsa bokaholimo ba mochini oa khatiso, mehato e mengata ea tlhokomelo e tlameha ho nkuoa, ho kenyelletsa:

1. Hloekisa bokaholimo: Sebelisa lesela le mongobo kapa borashe bo bonolo ho hloekisa bokaholimo ba mochini ho tlosa lerōle le holimo, litšila tsa oli le litšila tse ling.Ka mor'a ho hloekisa, e lokela ho hlakoloa hang-hang ho qoba mongobo le mafome holim'a mochine.

2. Sebelisa moemeli oa ho thibela mafome: U ka fafatsa kapa ua koahela lera la oli e thibelang mafome kapa pente holim'a mochine ho thibela bokaholimo ba mochine hore bo se ke ba e-ba le oxidized kapa mafome.

3. Tlhokomelo ea kamehla: E le ho sireletsa bokantle ba mochine oa khatiso ho tloha ho thulana ha mechine le mahlaseli a letsatsi a matla, tlhokomelo ea kamehla e ka etsoa khafetsa, joalo ka ho sebelisa lera la pente ea polishing.Likarolo tse tsamaeang le libaka tse nang le mocheso o matla oa letsatsi li lokela ho hlokomeloa kamehla letsatsi le leng le le leng ho netefatsa ts'ebetso e tsitsitseng ea nako e telele ea mochine.

2. Lubrication le tlhokomelo ea mechine ea khatiso

Nakong ea ts'ebetso ea mochini oa khatiso, ho hlokahala oli e ngata ea ho tlotsa ho netefatsa hore ho na le coefficient ea likhohlano lipakeng tsa likarolo tse fapaneng.Haeba lubrication e fokola, e tla tobana le ho hloleha ho hoholo ha lisebelisoa le mathata a tlhokomelo.Ka hona, ho tlotsa le ho hlokomela mochine oa khatiso oa mechine le oona ke oa bohlokoa haholo.

1. Khetha oli e loketseng ea ho tlotsa: E lokela ho hlahlojoa bukeng ea litaelo ea mochine oa khatiso, 'me oli e loketseng ea ho tlotsa e lokela ho khethoa ho ea ka maemo a ho sebetsa le mehlala ea mochine ho netefatsa phello e ntle ea lubrication.

2. Kamehla eketsa oli e tlotsang: Ka mor'a hore mochine oa khatiso o sebelisoe ka nako e itseng, oli e tlotsang e bonolo ho senyeha, ho fokotsa kapa ho lahleheloa.Pele o sebelisoa, hlahloba hore na boleng le pokello ea oli e tlotsang e fihlela litlhoko, 'me u tlatse oli e tlotsang ka nako.

3. Hloekisa likarolo tsa ho tlotsa: likarolo tse tsamaeang li bonolo ho bokella lerōle, lehlabathe le litšila tse ling, tse tla etsa hore oli e tlotsang e be litšila 'me coefficient ea likhohlano e eketsehe.Ka hona, hoa hlokahala ho hloekisa likarolo tse tsamaeang kamehla ho li boloka li hloekile ebile li hloekile.

3. Tlhokomelo ea mechine ea khatiso ea mechine

Sistimi ea motlakase ea mochini oa khatiso oa mochini ke karolo ea bohlokoa ea karolo e tloaelehileng ea mochini.Ka hona, hlahloba hore na tsamaiso ea motlakase e ka qala le ho sebetsa ka mokhoa o tloaelehileng letsatsi le leng le le leng.Haholo-holo ha u qala, bona hore na ho na le bothata ba ho qalisa khafetsa le ho emisa.Ho phaella moo, sebaka sa marang-rang sa tsamaiso ea motlakase le sona se lokela ho hlahlojoa ho netefatsa hore lithapo li na le motheo o motle le tšireletso.Sebakeng se pota-potileng plug ea linomoro tse peli, e lokela ho bolokoa e hloekile letsatsi le leng le le leng ho qoba mongobo kapa mongobo, e leng se bakang bahlahisi ba mochine oa mochine oa khatiso oa servo.

4. Tšireletso e feteletseng ea mechine ea khatiso ea mechine

Ha brake ea enjene kapa mochini oa khatiso o tletse, ho ka etsa hore mochini o se khone ho sebetsa ka mokhoa o tloaelehileng.Nakong ena, ho tlameha ho nahanoa ka lintlha tse ling tsa ts'ireletso ea boima bo feteletseng.

1. Kenya sesebelisoa sa ts'ireletso ea motlakase: Motlakase, o ka eketsa lisebelisoa tse ling tsa ts'ireletso ea lisebelisoa, joalo ka li-fuse, li sireletsang elektroniki, li-control controller, joalo-joalo, tse ka qobang ho se sebetse ha nako e khuts'oane kapa ho senya ho bakoang ke ho tlala.

2. Butle-butle qala mochine: Ha u qala mochine, u lokela ho qala ho fokotsa matla 'me u qale butle-butle ho qoba ho jara, hobane motlakase o qalang oa mochine o moholo, o ka etsang hore motlakase oohle oa tsamaiso ea matla a fokotsehe habonolo.

3. Etsa mosebetsi o motle oa ho qeta nako pele o tima: Ka mor'a ho sebelisa mochine, o lokela ho paka mochine ebe o bulela radiator le ho qeta mosebetsi ka mor'a ho sebelisa mochine oa khatiso ho tlosa mojaro.Mofuta oa oli e tlotsang o ka eketsa bophelo ba ts'ebeletso ea mochini.

(5) Qetello

Mochini oa khatiso oa mochini ke sesebelisoa sa bohlokoa sa indasteri.E le ho etsa hore e sebetse hantle, batho ba lokela ho etsa mosebetsi o motle oa ho lokisa le ho hlokomela mochine.Ho boloka mochine ka botlalo le ka nepo, hoa hlokahala ho tsepamisa maikutlo ho koetliso le thuto ea tlhokomelo ea mochine le tlhokomelo ea tlhahiso ea letsatsi le letsatsi ho netefatsa botsitso ba boleng ba sehlahisoa le polokeho le botsitso ba lisebelisoa.Ka tataiso e kaholimo, e ka boloka ts'ebeliso e tloaelehileng ea mochini, ea eketsa bophelo ba ts'ebeletso ea eona, 'me ea lumella mechini ea khatiso ea mochini hore e sebetse hantle tlhahiso le bophelo.

Nako ea poso: Phup-09-2023